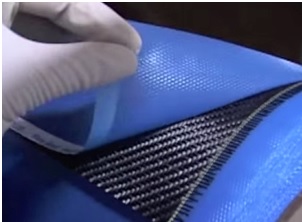

Pre-preg is pre-impregnated composite fibers where a thermoset polymer matrix material, such as epoxy, or a thermoplastic resin in a specified ratio. The fibers can be in form of spreaded unidirectional sheet of fibres/ biaxial woven fabric/multiaxial fabric, and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling and requires cold storage to prevent complete curing. It is normal for prepreg materials to be stored at temperatures of around -20°C since heat accelerates complete polymerization. The ratio of resin to reinforcement is known to be exactly right meaning that parts made from prepreg carbon fibre can consistently have this perfect resin (matrix) to reinforcement ratio. In addition, the manufacture of prepreg parts invariably involves the application of vacuum and elevated pressure such as an autoclave) resulting in excellent fibre consolidation, further enhancing the structural performance of the composite.