RAW MATERIAL SCENARIO FOR INDIAN COMPOSITE INDUSTRY

The major pillars of the composite industry are the “Hi-tech Fibres” such as glass, carbon; aramid and Polymer matrix such as; Thermoset and Thermoplastic Resins.

- Fibres

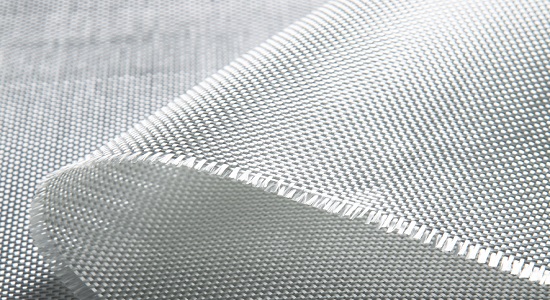

Glass Fiber continues as the preferred reinforcement material for fabricators, due to low cost and compatibility with the production processes. In 2018, glass fibers constituted markets share of around 98.5% and close to 20% of the domestic demand for glass fiber was made-up by import supply.

Carbon Fibers, Carbon fiber is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are aligned parallel to the long axis of the fiber with low cost to performance ratio, are the import dependent markets destined to grow. Carbon fibers are used mostly in Defense, Aerospace, Sporting goods and Automobiles sectors as a substitute for metals and ceramics. Formosa Plastics Corp., Taiwan, Kureha Corp., Japan, Toray Industries, Inc., Japan, Toho Tenax Co., Ltd., Japan, Osaka Gas Chemicals Co., Ltd., Japan and Toray Corporation, USA, are major exporters of Carbon fibers to India.

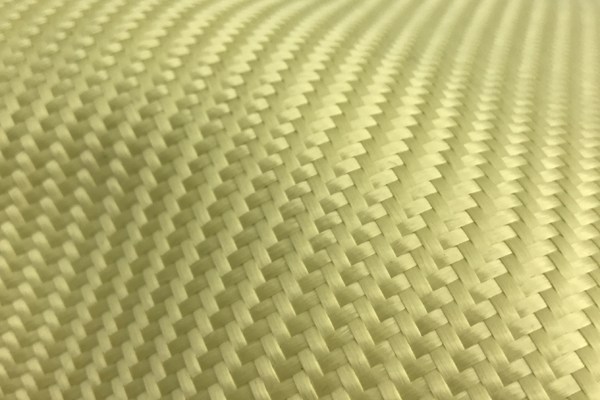

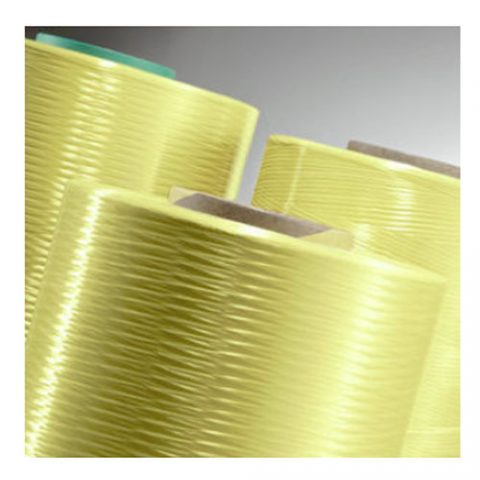

Aramid fibres are mainly used for protective bullet-proof jackets meant for personal protection. The demand of Aramid fibers is met by imports mostly through E. I. Du Pont De Nemours and Company, USA and Koninklijke DSM N.V., Netherlands.

- Resins

Unsaturated polyester resin (UPR) is the largest consumed resin, representing 83% of total Indian composites market. The total estimated consumption of UPR in India for the composite markets was around 155,210 MT in 2018. The Indian composites raw materials (UPR) industry is somewhat fragmented (around 60-70 manufacturers) & unorganized, however the market for epoxy resin was around 18,700 MT in 2018.